Position:Home > News > Application

What kind of rectifier bridge can satisfy the use of 6.6KW on-board charger?

——

Dilong China - Find a reliable car power supply manufacturer, order DC/DC converters, car chargers, Dilong New Energy is trustworthy. Dilong has been focusing on the power supply industry for 20 years, from China to the world, professional / reliable / cost-effective, it is worth choosing!

Generally refers to slow charging, refers to the charger installed on the electric vehicle.

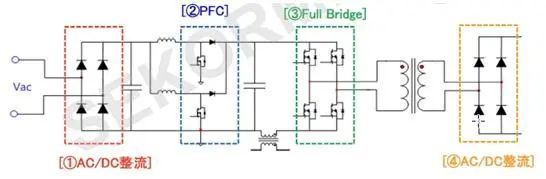

It can realize the function of AC input (85Vac-265Vac) and DC output (200Vdc-400Vdc) to charge the power battery. The core architecture of its circuit is mainly composed of two parts: boost PFC and LLC (DC/DC converter). The simple circuit block diagram of the on-board charger is shown in Figure 1 below.

For the input AC voltage 85Vac-265Vac, frequency 45Hz-70Hz, the maximum input current is 20A.

When connecting to the on-board charger through the power line, the AC/DC single-phase rectifier bridge must be processed first to convert the AC voltage into a DC pulsating voltage output (0.9*Uac). Then the voltage obtained after the large capacitor filtering process is about 120Vdc-375Vdc, and the processing of the input current and voltage is completed at this time. After that, it will enter the PFC boost, LLC full-bridge inverter and output rectification links, and finally output 200Vdc-400Vdc to provide DC voltage for the high-voltage battery pack.

01. High withstand voltage VRRM: Consider 1.5-2 times overvoltage, 220V AC input, generally choose 800V withstand voltage rectifier bridge;

02. High IFSM surge current withstand capability: the maximum input current is 20A, with 10 times the withstand current, 200A needs to be selected IFSM above;

03. Low VF: Lower VF means less heat generation and more stable performance;

04. High cost performance.

In view of the above four factors, this article recommends the high-performance and cost-effective on-board charger (OBC) products launched by Dilong new energy.

Its salient features can be summed up in six words: intelligence, safety, and efficiency.

High power factor: AC input adopts active power (PFC) factor correction, power factor ≥ 0.99, to achieve green grid;

high efficiency: the whole machine adopts LLC resonant soft switching technology, full-load efficiency ≥ 95.0%, low heat generation, reliability High;

wide voltage input range: AC220 (85V-265V) & AC380 (147V-457V), to meet the needs of domestic and foreign power grids;

easy installation: liquid-cooled/air-cooled sealed waterproof and dustproof structure, the temperature rise is lower than natural cooling , the whole machine has high reliability;

Intelligent charging: According to the battery state, it adopts the automatic conversion method of constant voltage, constant current and constant power state to charge, which effectively saves the charging time and prolongs the service life of the battery.

This shows that the on-board chargers launched by Dilong New Energy are excellent in any parameter. They are widely used in new energy vehicles, electric boats/boats, electric construction machinery vehicles and other fields.

Dilong New Energy is a technology-intensive high-tech enterprise, mainly focusing on the research and development, production and sales of on-board chargers, DC/DC converters and other products, and the products are supplied to the world.

As early as 2008, Dilong New Energy has entered the field of development and is one of the earliest manufacturers in the industry to achieve mass production of on-board chargers and DC/DC converters.

After years of accumulation of technical experience, Dilong New Energy has strong technical strength, product performance has been continuously improved, and has won the favor of many customers. For example, BAIC New Energy, BYD, Changan, Jianghuai, etc., which are the top ten sales of domestic new energy passenger vehicles, are all important customers of the company; King Long, Yutong, etc., which are the top ten sales of new energy passenger vehicles, are all important customers of the company;Foreign well-known BorgWarner, Webasto, Rimac, Denso Group, Volvo, etc. are all important customers of the company.

For a long time, Dilong New Energy has always insisted on continuous research and development investment, forming the three core advantages of Dilong New Energy.

The first is the advantage in R&D innovation. Dilong New Energy has a team of technical talents with advanced research and development concepts, focusing on independent research and development and innovation of new energy vehicle on-board power products, with solid professional knowledge and rich industry experience.

The second is the advantage in manufacturing. After more than ten years of production experience accumulation and process R&D innovation, Dilong New Energy has formed strong manufacturing advantages in automated production, production capacity scale and quality control.

The third is the advantage in customer resources. Dilong New Energy has been deeply involved in the vehicle power supply industry for many years. With its competitive advantages in R&D innovation, technology accumulation, manufacturing and product quality, it has accumulated a large number of OEM customer resources with strategic cooperative relations and has customer resource advantages. To sum up, Dilong New Energy is a very powerful manufacturer of on-board chargers and DC/DC converters.

If you want to purchase products or apply for samples, you can consult us directly, let us work together to create a better future.