Position:Home > News > Application

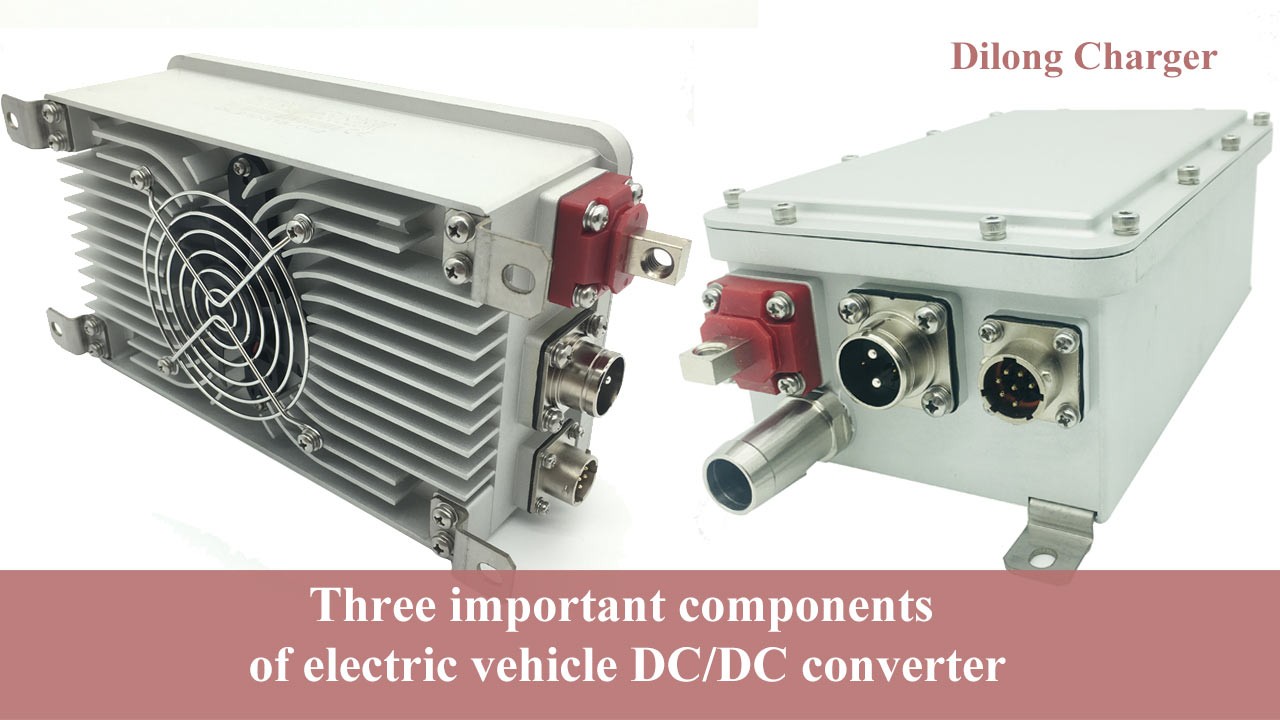

DC/DC converter is an important part of electric vehicle power system.

Its important function is to provide the required power for low-voltage vehicle electrical equipment such as power steering system and instrument panel, and to charge low-voltage batteries.

Its electric energy comes from the power battery pack, and the place is to supply power to the on-board electrical appliances.

The DC/DC converter has three important parts, namely the main circuit (power module), the drive module and the control module.

1. Main circuit

Also called power module, is the main body of the entire DC/DC converter.

2. Drive module

For the four-way drive signals output by the control chip, the four power switch tubes cannot be directly driven.

Therefore, the DC/DC converter needs to be equipped with a drive circuit to drive the power switch tube.

Each drive signal of the direct-coupled drive circuit drives the power switch tube through an amplifier circuit composed of two triodes. This method cannot realize the isolation of the control part from the main circuit.

The pulse transformer-coupled drive circuit adds a pulse transformer on the basis of the direct-coupling type. The isolation of the control circuit and the main circuit is realized, but the disadvantage of this structure is that the design and manufacture of the transformer is complicated.

In order to drive the power switch tube more conveniently, many companies (such as Dilong New Energy) use driver chips. The driver chip can output a large power to drive the switch tube, and with the miniaturization of the chip, the current driver chip is very small in size and has various packaging forms.

3. Control module

The feedback of the main circuit mainly has three control modes, namely the voltage control mode, the peak current control mode and the average current control mode.

The voltage control mode belongs to voltage feedback, which uses the output voltage for correction. It is a single-loop feedback mode. The output voltage is sampled and compared with the input reference voltage, and the PWM wave signal is output.

The design and application of the voltage control mode are relatively simple, but the voltage control mode does not control the output current, so there is a certain error, and the output voltage is filtered by the inductor and capacitor first, which makes the dynamic response relatively poor.

The difference between the peak current control mode and the voltage control mode is that in the peak current control mode, the sawtooth waveform of the voltage control mode is converted into the superposition of the instantaneous current of the inductor and a small sawtooth wave, but the instantaneous current of the inductor cannot be used. Indicates the condition of the average current. The average current control mode belongs to the double-loop control mode.

The output signal of the voltage loop is compared as the feedback signal of the reference current and the inductor current, and the error amplifier is set, Some high-frequency components of the input current can be averaged, the averaged output current can be compared with the sawtooth wave generated by the chip, and an appropriate PWM waveform can be output.

Compared with the three control methods, the average current control method does not limit the duty cycle, and feedbacks both the output voltage and the inductor current, which has a better control effect.

4. Manufacturer introduction

Dilong New Energy is a subsidiary of Dilong Group, relying on the group's 20 years of R&D and production experience in the power supply industry. Focus on the research and development, production and sales of new energy vehicle DC/DC converters, on-board chargers (OBC)... and other on-board power products.

Over the years, it has been deeply engaged in R&D and innovation, and the strong R&D team and strong technical strength enable the company to provide customers with customized solutions for vehicle power supplies quickly and flexibly.

Dilong New Energy has passed the IATF16949:2016 automotive industry quality management system certification, and has an automotive-grade standardized professional factory. And took the lead in completing the fully automated production process, and has the large-scale production capacity of on-board DC/DC converters and other on-board power products.

With its leading technical advantages, reliable product quality and excellent service quality, the company has won the trust and recognition of many customers from domestic and international.

At present, there are more than 400 new energy vehicle manufacturers in cooperation around the world, and many of them have world-class OEM customers.

Dilong New Energy is committed to becoming a world-leading high-quality supplier of automotive power products and system solutions. With the spirit of keeping improving and taking product quality as life, we continue to innovate and iterate to produce and manufacture automotive power supply products with superior performance and reliable quality, which are supplied to the world.

5. Dilong DC/DC converter products

The company's vehicle-mounted DC/DC converter products adopt full digital design, as well as advanced LLC resonance technology and soft switching technology for production. And built-in DSP high-speed processor, it has the core advantages of high efficiency, high power density, reliable operation, small size and high security. It has been recognized by many customers at home and abroad, and is widely used in various fields of new energy vehicles, as well as electric boats, electric boats and other fields.

The output power of the company's products covers 0.3KW-5KW, which fully meets the market demand for DC/DC converters with different powers.

Among them, 1.5KW, 2KW and 3KW are the most widely used in the field of new energy electric vehicles and passenger vehicles. It has a wide voltage input range to meet the electricity standard requirements of many countries including China, the United States, Japan, Germany, etc., and can be customized for different needs of customers.

Dilong New Energy DC/DC converter products have undergone rigorous testing and verification before leaving the factory, such as high and low temperature, vibration, salt spray, cycle conditions, surge, electromagnetic compatibility, etc. It has been verified by actual roads and operating conditions in different environments for many years, and the operation is stable and reliable, ensuring the safe driving of vehicles in various harsh environments.

This DC/DC converter series uses the most efficient CAN communication, higher working efficiency, and focuses on electromagnetic compatibility and good heat dissipation conditions. It has significant advantages such as small size, high efficiency, stable output, convenient installation, strong anti-interference ability, complete protection, good heat dissipation effect, and long service life.