Position:Home > News > Application

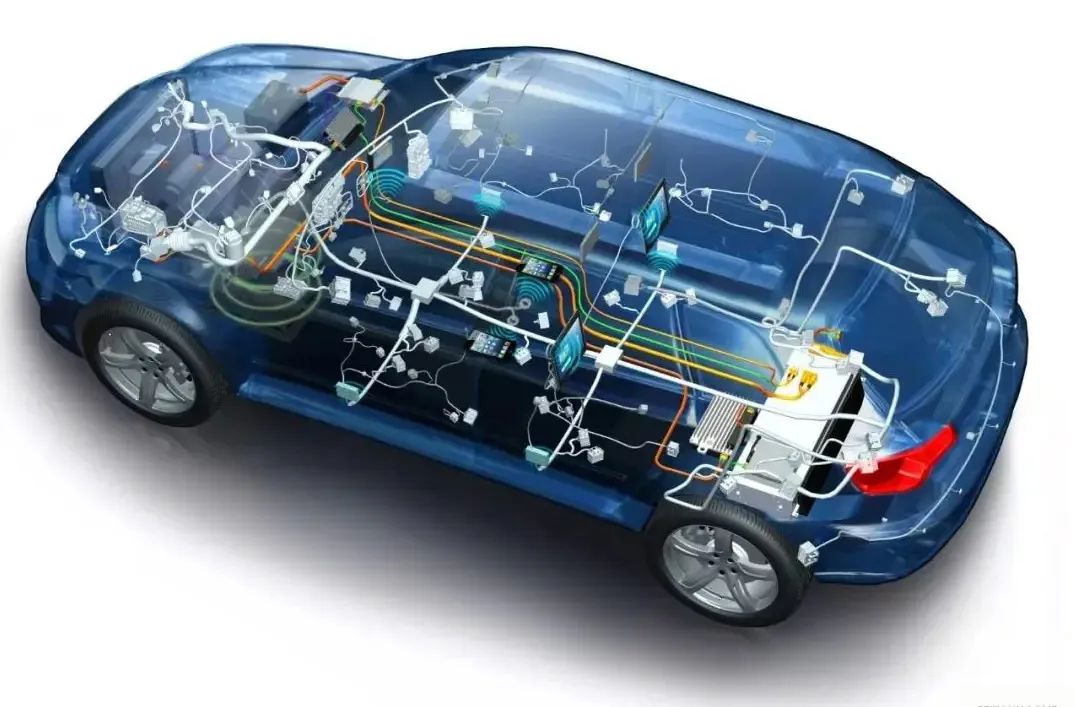

We all know that traditional fuel vehicles are driven by engines, while electric vehicles (EV) are driven by motors. The power source of the motor is a battery pack that can be recharged and can store electricity. In an electric vehicle, the voltage of the battery is relatively high and the current is also large. Therefore, the requirements for battery management and utilization far exceed the requirements for batteries in traditional fuel vehicles.

Now in order to improve the charging efficiency and charging speed, it is necessary to complete the charging of the battery pack in a period calculated in minutes, rather than the usual calculation in hours. Let's take an example. For example, if you want to charge an electric vehicle battery pack with a battery capacity of 30KWh, if you want to fully charge it within 15 minutes, the charging power will reach 120kw. Assuming that the charging voltage of the electric vehicle is 200-400v, then the corresponding Its charging current will reach 300A.

Such a large current is difficult to achieve if we only use a single power module. In the face of the increasing power of chargers, a solution needs to be found, and parallel current sharing is undoubtedly one of the best solutions. Dilong OBC also adopts this solution, because current sharing has the advantages of strong capacity expansion, convenient expansion, easy implementation of program changes and upgrades, and low cost, so software current sharing methods are often used in the implementation process, but in the implementation The key problem that needs to be solved in the process of capacity increase is the problem of communication between modules.

01.Advantages and characteristics of CAN bus

The CAN bus itself has the advantages of high reliability, low cost, simplicity and practicality, and has high network security, so it has been used more and more. At present, the CAN bus has been developed into an electric vehicle electronic system as an international standard. mainstream bus. For example, the communication between internal modules of Dilong car charger adopts the software current sharing scheme based on CAN bus. In view of the fact that the electric vehicle charger needs to communicate with the battery management system (BMS), and because of the high network security of the CAN bus, the CAN bus is used as the communication method between the charger and the battery management system, and And because the communication distance of the CAN bus is relatively long (10KM) and the reliability is high, the communication between the vehicle monitoring system and the charger also adopts the CAN communication method.

The research on the CAN bus in this paper mainly focuses on how to apply the CAN bus to the charger OBC, and complete the communication process between the charger and the battery management system (BMS), internal power module and monitoring system during the working process.

02.Communication Topology for Electric Vehicle Chargers

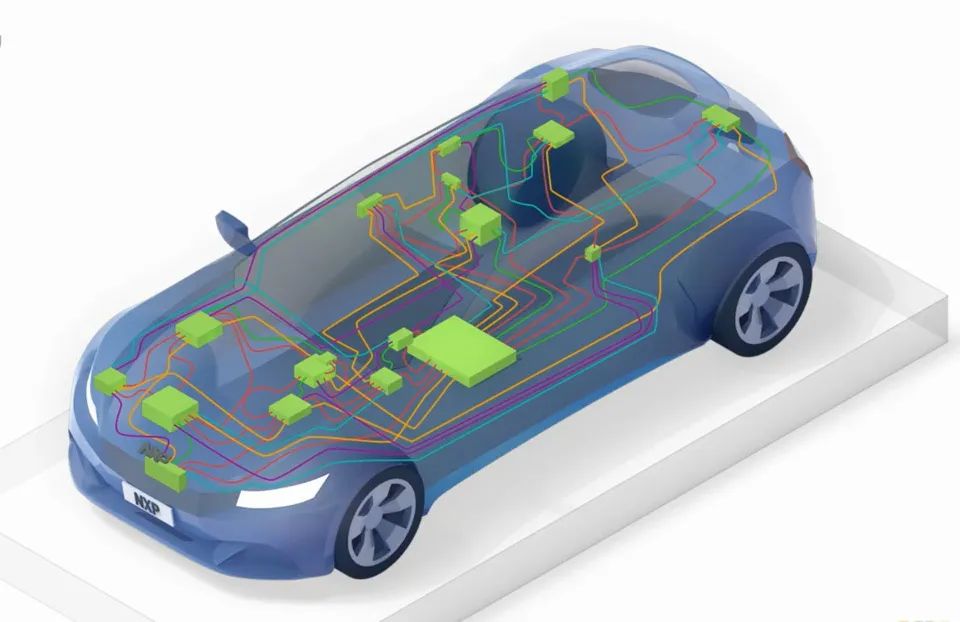

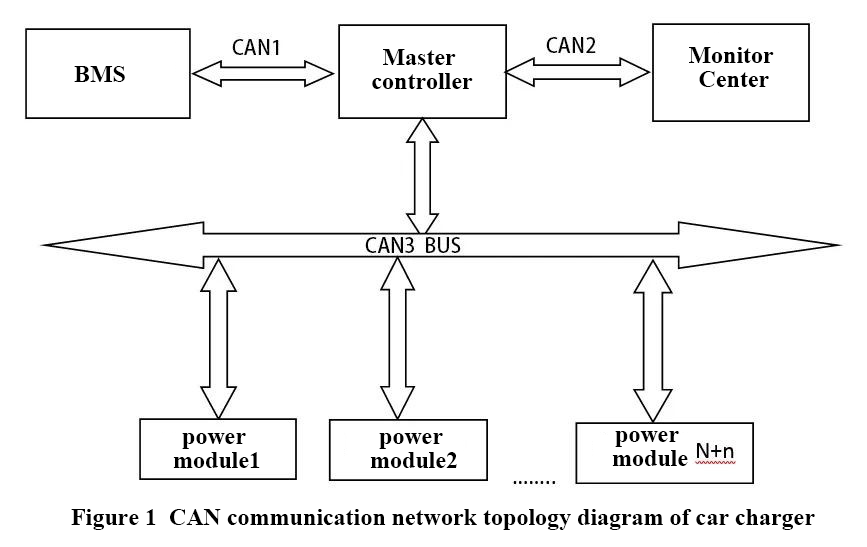

We said above that the electric vehicle charger needs to communicate with the battery management system (BMS), the centralized monitoring center of the charging station and the internal power module during the working process. The topological diagrams of the three CAN communication networks are as follows:

1. In the charger, the communication network (CAN1) between the main controller and the battery management system (BMS): it is mainly used to exchange data between the charger and the on-board battery management system, and provide parameters for power battery charging information.

2. The communication network (CAN2) between the main controller of the charger and the charging monitoring system: Realize the real-time data collection, monitoring and control functions between the monitoring center and the charging machine, and can grasp the working status of the charging machine through the monitoring center in real time, and The battery information can be obtained indirectly through the charger.

3. The communication network (CAN3) between the main controller of the charger and the power module: realize the data exchange between the main controller of the charger and the independent power module, realize the software current sharing scheme based on the CAN bus, in which n power modules As a working module, n power modules are used as backup power modules.

The CAN network is applied to the electric vehicle charger, mainly based on the working principle of the charger and combined with the working characteristics of the CAN bus, to formulate a suitable work flow chart based on CAN bus communication.

03.Application of CAN bus

With the promotion of CAN bus in the world, its use in electric vehicle charger OBC will become more and more extensive.

For example, Dilong New Energy, a professional manufacturer of on-board chargers in China, uses CAN2.0B high-speed communication for its on-board chargers. Its advantages are summarized as follows:

1. Realized high-speed intelligent communication with BMS, which can intelligently judge whether the battery connection status is correct.

2. It can obtain the battery system parameters, as well as the real-time data of the whole group and single battery before charging and during charging.

3. It has the function of communicating with the vehicle monitoring system, intelligently uploads the working status, working parameters and fault alarm information of the on-board charger, and accepts the control commands to start and stop charging.

4. In addition to the intelligent communication function, it also has complete safety protection functions, such as overvoltage, undervoltage, overcurrent, short circuit, overtemperature protection, etc.

5. During the charging process, it can also ensure that the temperature of the battery and the charging current and voltage do not exceed the allowable value.

6. Automatically dynamically and intelligently adjust the charging current according to the battery information of the BMS, and automatically judge whether the charging connector is connected correctly.

Attachment: Dilong new energy manufacturer introduction

Dilong New Energy, as a wholly-owned subsidiary of Dilong Group, relies on the parent company’s 20 years of deep accumulation in the field of power supply research and development and production. The main research directions are electric vehicle on-board chargers, on-board DC/DC converters, and on-board two-in-one , Three-in-one and other products.

Dilong Group covers an area of 100,000 square meters, has passed a number of professional and system certifications at home and abroad, has a number of independent intellectual property rights, and has a standard automated production process. It can provide global customers with high-efficiency, high-power-density, intelligent and highly reliable vehicle power supply products.

At present, the company's products are supported by more than 200 domestic and foreign car manufacturers, and it is a world-renowned supplier of vehicle power supplies.

Dilong will continue to consolidate its advantages and strive to develop and innovate, providing all-round, high-volume, customized and professional product services and solutions for global car manufacturers.